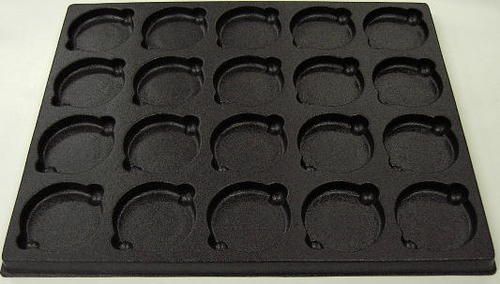

Vacumm Forming Packaging Tray

Product Details:

- Product Type Vacumm Forming Packaging Tray

- Material PVC

- Hardness Hard

- Color Black

- Click to View more

Vacumm Forming Packaging Tray Price And Quantity

- 1000 Box

Vacumm Forming Packaging Tray Product Specifications

- PVC

- Hard

- Black

- Vacumm Forming Packaging Tray

Vacumm Forming Packaging Tray Trade Information

- 100000 Box Per Week

- 8 Days

Product Description

Vacuum forming (vacuuforming), is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying vacuum between the mold surface and the sheet. The vacuum forming process can be used to make most product packaging, speaker casings and even car dashboards.

Usage

Unit dose packaging of Pharmaceuticals:

Blister packs are commonly used as unit-dose packaging for pharmaceutical tablets, capsules or lozenges. Blister packs can provide barrier protection for shelf life requirements, and a degree of tamper resistance. In India, blister packs are mainly used for packing physician samples of drug products, or for Over The Counter (OTC) products in the chemist shops. In other parts of the world, blister packs are the main packaging type since pharmacy dispensing and re-packaging are not common.

A series of blister cavities is sometimes called a blister card or blister strip as well as blister pack. In some parts of the world the blister pack is known as a Push-Through-Pack (PTP). The main advantages of unit-dose blister packs over other methods of packing pharmaceutical products are the assurance of product/packaging integrity (including shelflife) of each individual dose and the possibility to create a compliance pack or calendar pack by printing the days of the week above each dose. Blister packs also hinder the use of OTC drugs in the manufacture of illegal drugs.

Blister packs are created by means of a form-fill-seal process at the pharmaceutical company or designated contract packer. A form-fill-seal process means that the blister pack is created from rolls of flat sheet or film, filled with the pharmaceutical product and closed (sealed) on the same equipment. Such equipment is called a blisterline.

Consumer goods:

Other types of blister packs consist of carded packaging where goods such as toys, hardware, and electrical items are contained between a specially made paperboard card and clear pre-formed plastic such as PVC. The consumer can visually examine the product through the transparent plastic. The plastic shell is vacuum-formed around a mold so it can contain the item snugly. The card is brightly colored and designed depending on the item inside, and the PVC is affixed to the card using heat and pressure to activate an adhesive (heat seal coating) on the blister card. The adhesive is strong enough so that the pack may hang on a peg, but weak enough so so that the package can be easily opened (in theory). Sometimes, with large items, the card has a perforated window for access.